medical magnesium has been committed to one goal since it was founded: We want to provide surgeons with highly functional absorbable implants. Therefore, we are using expertise from all technical and clinical areas to achieve the best possible result. For each implant, we use the best possible alternative in terms of manufacture, packaging and clinical handling.

Cooperation with clinics

Since the beginning of the mission to develop the next generation of resorbable implants, we have been looking for close contact with clinical partners who, with their ideas and practical experience, make an enormous contribution to the final implant solutions.

The ideal implant is designed when the needs of the patient, the operating surgeon and the medical staff are included at the beginning of the development and are regularly queried during the process. We look forward to every request from clinics.

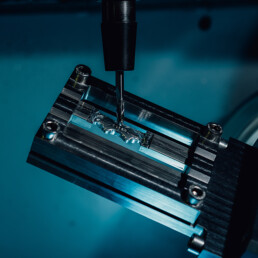

Quality

The entire production chain works in accordance with the international quality standard DIN EN ISO 13485. The performance and the consistently high quality are regularly checked and permanently monitored.

In addition to these required standards, innovative measurement methods and test procedures are used to understand the products down to the last detail.

Research location Aachen

Aachen stands for high technology and technical innovation. We develop and produce medical implants in this fertile environment. Our team consists largely of graduates from RWTH Aachen University.

We are very proud to be able to represent the major part of the production chain for implants in Aachen and to be able to continue to grow here at the location.

Team

medical magnesium is backed by a interdisciplinary and motivated team. The entire team is working towards the goal of providing patients and users with high quality products while having fun.

Research projects

We are pleased to be part of various research projects in exciting networks. Together with leading institutions, we are working on approaches to improve surgical care. With these results, the implants are further refined to meet the requirements of modern clinical care. We look forward to exploring the potential of magnesium technology in many medical indications.

RePlaSys

Development of an innovative absorbable plate system made of magnesium

Within the trauma and accident surgery, fractures in the foot area represent one of the most frequent and health-economically significant treatments. The current standard of care for fractures in the foot area is surgical implantation of titanium plates, which in many cases requires removal of the implant material in a second intervention after the fracture has healed.

Furthermore, this results in high and increasing health-economic costs, in addition to the additional painful rehabilitation and the risk of infection for the patient.

The aim of the project is the application-oriented development of an innovative absorbable plate system made of magnesium that augments the bone grafting while the implant is being degraded. For this purpose, the required implant technology is simulated and optimised in a computer model in cooperation with the Institute for General Mechanics at the RWTH Aachen University and the Institute for Laboratory Animal Science at the University Hospital Aachen. Furthermore, the resulting plate designs will be biomechanically tested. The effectiveness of the new plate design will then be evaluated in a preclinical study.

Partner(s):

MagNumGo

Optimization of the current standard of care by developing an implant that promotes bone growth

One of the sports medicine treatments with the highest number of cases and the most importance in terms of health economics is the reconstruction of cruciate ligaments. For this purpose, according to the current standard of care for cruciate ligament tears, an operative transplantation of tendon grafts is carried out, which are fixed in the bone by resorbable plastic screws. This research project aims to clinically assess an innovative type of surgical therapy.

The research content is the development of the mm.IF, an absorbable magnesium screw for the reconstruction of the anterior cruciate ligament, which is physiologically degraded after the tendon graft has healed and at the same time forms new bone tissues.

Fibrograft

Development of a composite material made of magnesium and fibroin for use as a bone substitute material

In an aging society, the regeneration and natural replacement of tissue play an increasingly important role. Due to the limited availability of the body’s own transplants, an important aspect of material development is the processing of materials into complex carrier structures, which could enable the targeted formation of certain types of tissue through stem cell therapy and tissue engineering.

An alternative is naturally obtained silk fibroin from the cocoon of the mulberry moth.

As part of the project, a new and natural dissolving process is used, which enables the production of various shapes and structures with adjustable microstructure. This enables a targeted differentiation of stem cells into the most important types of tissue. The sub-goal of medical magnesium is the development of a suitable magnesium structure which, in combination with the material technology of the fibroin solution, forms a composite material and can be used as a bone substitute material.

This project is funded by the European Regional Development Fund (ERDF).

Funding&Partner(s):

medical magnesium x EIT Health

medical magnesium is an active member of the EIT health community is proud to receive and give support to the great number of healthcare startups in this iniative.